Visual management and lean in the Environment and Energy sector

Lean and visual management aim to reduce losses. It is self-evident that the application of visual management is also suitable for the Environment and Energy sector. Failure, waste and surplus production are losses that can be easily addressed using lean tools. This will result in reduction of losses, improvement of cost structure and a safer working environment.

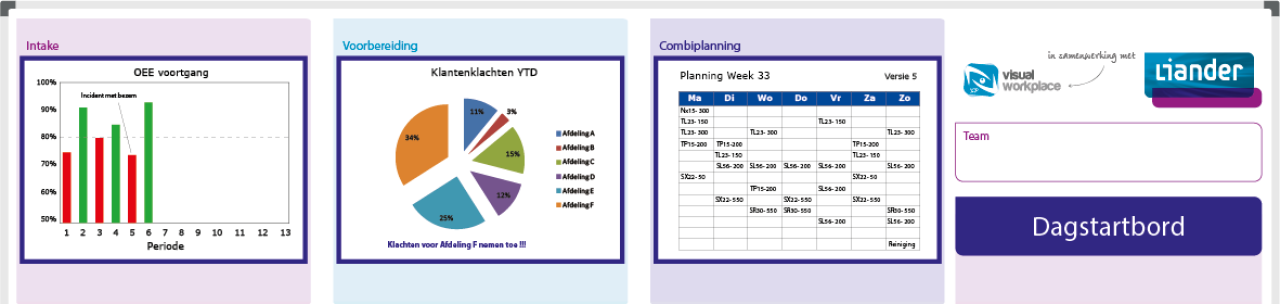

Energy sector

The energy sector has changed dramatically in recent years. The free market, the splitting of energy companies, mergers and smart energy meters are examples of this. In addition, there is more focus on sustainability and customer satisfaction. As a result, several companies in the energy sector have been using lean to optimise operational efficiency. Below there are a few applications of visual management in the Environment and Energy sector.

Improvement boards

Improvement processes are central in the lean philosophy within the energy sector. We have developed an improvement board for a national power company, which is being used to initiate and monitor improvement proposals. The team members can submit A4 improvement proposals on the left side of the board. The proposals are presented in magnetic windows in various colours. The improvement team can assess the proposals and can place them in the columns "in preparation" or "in progress" places. The team can then set the proposal in motion and it will be noted on the right side of the board. This type of improvement board has been rolled out nationwide.

PDCA improvement boards

Within the lean method, the PDCA cycle plays an important role. We developed a PDCA cycle improvement board for a water authority in the south-east of the Netherlands with the PDCA circle in eight steps.

In step 1 and 2 a problem and an objective are determined. In step 3 and 4, the problem is analysed and solutions are devised. In steps 5 and 6 actions are planned and implemented. And in the last steps, the effect is measured and standardised. The team uses the PDCA improvement board as a tool to go through the process. We developed a PDCA poster for a national energy company. Using the posters, the staff are trained in the PDCA process.

Curious?

Are you curious about the possibilities for your organisation? We love to brainstorm about the best opportunities and solutions for you.

Tailor-made service and giving advice is what we do. Contact TnP.